Eyeliner is an essential beauty product that helps define the eyes, adding depth and drama to any makeup look. Whether it’s for a subtle enhancement or a bold statement, eyeliner plays a crucial role in beauty routines worldwide. But have you ever wondered what goes into making the perfect eyeliner? From the choice of ingredients to the manufacturing techniques, every detail counts.

In this article, we’ll explore the process of how eyeliner is made, the key ingredients that go into it, and the technologies behind its creation.

Key Ingredients in Eyeliner

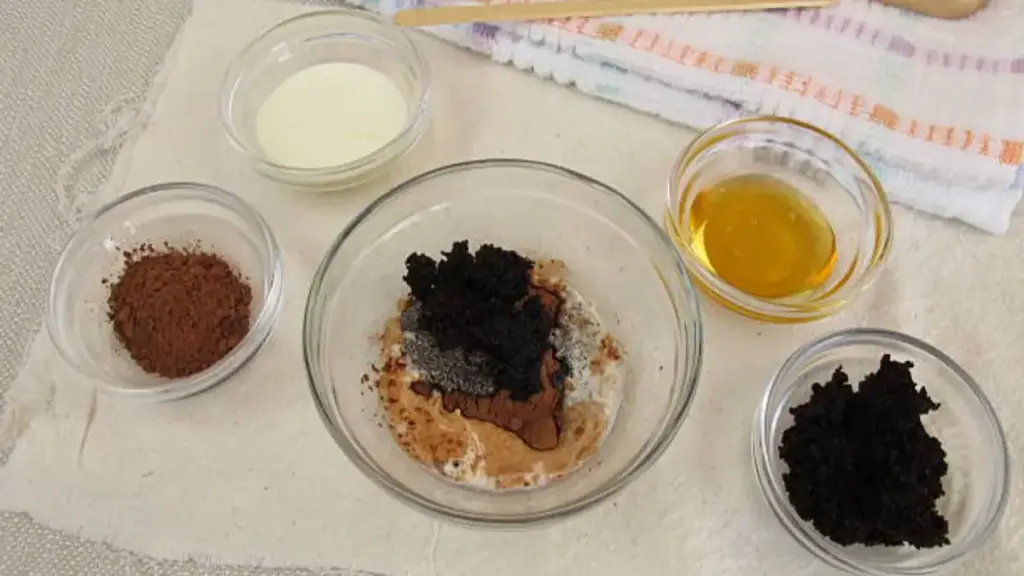

The foundation of any eyeliner lies in its ingredients, which contribute to its texture, longevity, and performance. While the ingredients may vary slightly depending on the type of eyeliner (gel, pencil, liquid), there are several key components that most formulations share.

- Pigmentos

Pigments are what give eyeliner its color. Common pigments used in eyeliners include carbon black for a rich, intense black shade, and various iron oxides for different hues, such as brown and gray. These pigments are mixed with oils and other ingredients to create the right consistency and color payoff.

- Ceras

Waxes help solidify the eyeliner, giving it structure. For pencils, beeswax or carnauba wax is commonly used. In gel eyeliners, synthetic waxes such as microcrystalline wax are preferred for their smooth texture and ability to hold the pigment without smudging.

- Oils and Emollients

Oils such as castor oil and mineral oil are used to enhance the smoothness and spreadability of the product. These ingredients also help the eyeliner glide on easily, making application smoother, while also providing a certain level of moisture to the skin around the eyes.

- Conservantes

Preservatives are essential in makeup formulations, ensuring that the product remains safe and effective over time. Parabens, phenoxyethanol, and other preservatives are commonly included to prevent the growth of bacteria and fungi, particularly in liquid and gel eyeliners.

- Ligantes

Binders like magnesium stearate are used to hold the various components of the eyeliner together, ensuring that the product remains uniform in texture and doesn’t separate over time.

How Different Eyeliner Types Are Made?

Delineador comes in various forms, including gel, pencil, and liquid. While the ingredients are often similar, the manufacturing process for each type varies to cater to different eye shapes and application preferences.

Delineador em gel

Gel eyeliners are a popular choice for those seeking a creamy, smooth finish. The production process typically begins with combining pigments, waxes, and oils to create a thick, paste-like consistency. This mixture is heated to melt the waxes and ensure even distribution of the pigments. The gel is then poured into containers and cooled. Some formulas may also include silicones to enhance the product’s durability and prevent smudging.

Lápis delineador

Pencil eyeliners are among the most traditional and widely used. To make a pencil eyeliner, the key ingredients are mixed together in a solid form and then extruded into long, thin shapes. The pencils are then sharpened to a fine point, making them ready for application. One unique aspect of pencil eyeliner is that it often contains additional ingredients like talc or kaolin clay, which give it a more powdery texture.

Delineador líquido

Liquid eyeliners are known for their precision and intense color payoff. To make liquid eyeliner, a combination of pigments, water, and various thickeners is mixed. The formula is usually more fluid than gel or pencil, giving it a smooth application. In some cases, alcohol is added to ensure quick drying. The mixture is then placed into bottles with a fine-tip applicator, ready for use.

The Science Behind Eyeliner Formulas

The performance of an eyeliner is deeply rooted in its formulation. Each characteristic is the result of a carefully crafted balance of ingredients to achieve the desired effect for users.

Textura

The smoothness of an eyeliner comes from the balance of waxes and oils. Waxes like beeswax provide structure, while oils (e.g., castor oil) ensure easy application, allowing the product to glide effortlessly over the skin.

Color Vibrancy

Pigments are essential for creating bold, vibrant shades. The quality and concentration of pigments like carbon black or iron oxide impact how rich and intense the color appears. Fine pigment dispersion ensures an even application.

Longevidade

To ensure long-lasting wear, formulators use silicone-based ingredients or film-formers that adhere to the skin without fading. These components create a flexible layer that stays intact for hours, even with constant movement. A trusted eyeliner brand, like Siloran can really elevate the wear time of your eyeliner, giving you the confidence to go through your day without worrying about touch-ups.

Water Resistance

The ability to resist water is achieved by incorporating hydrophobic ingredients, such as silicone elastomers or natural waxes. These form a protective barrier, preventing smudging and ensuring that the eyeliner holds up against moisture and humidity.

The Eyeliner Manufacturing Process

O manufacturing of eyeliner involves several critical steps to ensure product consistency and quality.

- Ingredient Mixing

All ingredients—pigments, waxes, oils, and preservatives—are measured and combined in large mixers. This is done at a specific temperature to ensure that the ingredients blend together properly and maintain a consistent texture.

- Heating and Cooling

For gel and liquid eyeliners, the mixture is heated to melt the waxes and dissolve the pigments. Once the desired consistency is achieved, the mixture is allowed to cool. This step is crucial in ensuring that the eyeliner holds its form once packaged.

- Filling and Packaging

The final product is poured into containers such as jars for gel eyeliners, tubes for liquid eyeliners, or sharpenable pencils for pencil eyeliners. The packaging is carefully chosen to preserve the formula and provide an easy application experience.

How Eyeliner Colors Are Made?

Color creation in eyeliners is an art form in itself, with makeup enthusiasts and professionals developing the vibrant and diverse color range available today. Here’s a look at how some popular eyeliner colors are made:

- Branco: Titanium Dioxide

- Vermelho: Carmine or Iron Oxide Red

- Blue: Ultramarine Blue or Chromium Hydroxide

- Roxo: Manganese Violet

- Verde: Chromium Oxide Green

For those looking for a bit more sparkle or shine, metallic and shimmer eyeliners often include mica or finely milled aluminum to create a reflective, glittery finish. These ingredients enhance both the visual impact and the longevity of the eyeliner.

Eyeliner Quality Control

Eyeliner undergoes several quality control tests to ensure it meets high standards. These include:

- Texture and Color Consistency: Ensuring uniformity in both texture and pigmentation across batches.

- Packaging Integrity: Verifying the packaging is secure to avoid contamination and maintain hygiene.

- Testes de segurança: Conducting dermatological and ophthalmological tests to confirm the product is safe for sensitive areas like the eyes.

- Performance Testing: Checking for smudge resistance, waterproofing, and ease of removal to meet user expectations.

Sustainable and Innovative Eyeliner Production

Sustainability and innovation are reshaping the eyeliner manufacturing process. Many cruelty-free brands are leading the way by adopting eco-friendly practices, such as using sustainably sourced ingredients, reducing plastic packaging, and minimizing waste. Refillable eyeliner pens are also becoming more common, helping to reduce the reliance on disposable plastics in packaging.

In terms of ingredients, natural and organic pigments are increasingly popular, with paraben-free factories focusing on creating formulations free of harmful chemicals. These brands are responding to growing consumer demand for safer, more environmentally responsible products. At the same time, advancements in eyeliner technology continue to emerge. New waterproof formulas are more durable than ever, offering extended wear without fading or smudging. Innovations in brush technology have led to more precise applicators, making it easier to create both bold lines and delicate wings.

Moreover, some eyeliner manufacturers are exploring biotechnology, developing plant-based alternatives to synthetic ingredients, and creating formulations that are gentler on the skin, making them suitable for sensitive eyes. These efforts reflect a broader commitment to both sustainability and innovation in the cosmetic industry.

Conclusão

Making eyeliner is a precise mix of science and creativity, resulting in a product that’s both functional and beautiful. As the industry evolves, we can expect even more innovation in formulations.

Ready to experience high-quality, long-lasting eyeliner for your brand? Trust Siloran to deliver the best.